Ntau zaus hloov huab cua, cov av noo thiab qhov kub tsis tshua muaj peev xwm ua rau muaj kev cuam tshuam loj rau lub tsev facades, pob zeb, hlau thiab cib. Txhawm rau tiv thaiv qhov no los ntawm qhov tshwm sim, nws yog txoj cai los npog cov chaw zoo li no nrog cov txheej txheem ntawm cov xim tiv thaiv thiab cov kua roj vanish, uas txo qhov kev cuam tshuam ntawm ib puag ncig kev txhoj puab heev ntawm lub hauv paus. Ib qho ntawm cov khoom no yog KO-174 enamel. Xav txog nws cov yam ntxwv tseem ceeb thiab daim ntawv thov nta.

piav qhia khoom

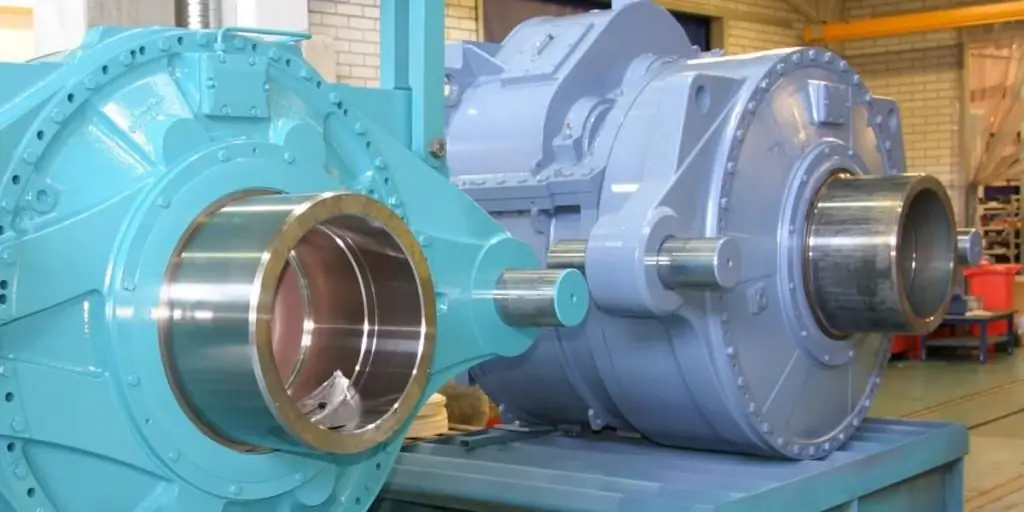

Kev tiv thaiv thiab kho kom zoo nkauj ntawm facades thiab lwm txoj hauv kev yog lub hom phiaj tseem ceeb ntawm KO-174 enamel. Tsis tas li, muaj pes tsawg leeg tuaj yeem siv los tiv thaiv cov txheej txheem xeb ntawm cov hlau, cov kav dej thiab kev sib txuas lus ua haujlwm hauv ib puag ncig hnyav.

Nws tseem yog ib qho tseem ceeb uas cov txheej txheem yooj yim tiv taus cov av noo thiab kub hauv thaj tsam ntawm -60… + 150 ° C. Qhov no nthuav dav dav ntawm nws daim ntawv thov.

Khoom KO-174 belongs rau pab pawg ntawm cov khoom sib xyaw ua ke nrog txaus tiv thaiv cov kab hluav taws xob ultraviolet. Lub hauv paus yogsilicone varnishes nrog ntxiv cov kuab tshuaj, xim pigments thiab hloov kho additives.

Cov txheej yog yooj yim rau kev thov thiab muaj qhov zoo heev adhesion rau cov substrate kho. Rau tag nrho nws lub zog, cov yeeb yaj kiab khov muaj peev xwm dhau los ntawm huab cua thiab chav los ntawm nws tus kheej, uas yog qhov tseem ceeb heev thaum siv cov enamel ntawm cov facades ntawm thaj chaw nyob.

Cov yam ntxwv ntawm silicone enamel KO-174 thiab cov khoom lag luam

Technology rau zus tau tej cov tshav kub-resistant enamel yog tswj los ntawm TU. Cov ntaub ntawv tswj hwm hais tias cov khoom kawg yuav tsum muaj cov khoom nram qab no:

- viscosity (thaum ntsuas nrog viscometer) raws li B3-246 - tsawg kawg 20 units;

- ua rau qhov kub siab tshaj plaws (+ 150 ° C) - tsis tsawg dua 3 teev;

- tawv txheej txheej cuam tshuam lub zog (raws li U-1 ntsuas) - txog 40 units;

- hardness - tsis tsawg dua 0.3 rel. units;

- zaj duab xis khoov elasticity - tsis ntau tshaj 1 hli;

- adhesion ntawm cov muaj pes tsawg leeg nrog lub hauv paus - 2 ntsiab lus;

- dej tsis kam - 24 teev;

- ntau feem ntawm cov khoom tsis hloov pauv (nyob ntawm xim) - 35-55%.

Enamel KO-174 yog ib qho hnav, matte tiav. Lub sij hawm ziab ntawm ib txheej mus txog qib 3 yog li 2 teev (ntawm qhov kub ntawm +20 ° C).

Nyob rau hauv tsev txee muaj cov khoom sib xyaw ntawm dawb, beige, ci daj, xiav, xiav, liab, ntsuab, grey, dub thiab nyiaj.

Main Applications

Cov yam ntxwv zoo ntawm silicone enamel KO-174 tso cai rau nws siv rau hauv cov xwm txheej nyuaj tshaj plaws. Feem ntau, cov txheej txheem yog siv los ntawm cov tuam ntxhab ntawm cov qauv hlau txhawm rau txhawm rau txhawm rau khaws cia ntev ntawm cov khoom zoo li.

Tsis tas li, cov khoom xyaw nquag siv hauv cov hauv qab no:

- Kev thauj mus los. Cov txheej tiv thaiv tiv thaiv corrosion ntawm cov khoom hla hla, txuas hniav, hla hla, hlau thiab pob zeb txhawb nqa, hla hla, thiab lwm yam.

- Kev lag luam hluav taws xob. Cov txheej tiv thaiv cov qauv hlau thiab cov facades raug qhov kub thiab txias hauv thaj tsam ntawm -60… + 150 °С.

- Kev lag luam hlau. Enamel yog siv los tiv thaiv corrosion ntawm cov tsev thiab chaw ua haujlwm.

- Tshuaj lom neeg kev lag luam. Cov khoom sib xyaw ntawm hom no yog siv los ua kom pom qhov pom zoo rau cov hlau thiab cov pob zeb ua vaj tse uas raug rau ib puag ncig nruj.

- Agro-industrial complexes thiab civil engineering. Kev tiv thaiv muaj pes tsawg leeg KO-174 yog siv los tiv thaiv corrosion thiab kho kom zoo nkauj pleev xim ntawm facades thiab ntim rau ntau lub hom phiaj.

Vim tias organosilicon enamel (KO-174) ntawm cov xim sib txawv tuaj yeem yuav ntawm txhua lub khw tshwj xeeb, cov khoom sib xyaw yog nrov heev hauv kev tsim kho. Qhov no tau yooj yim los ntawm qhov tseeb tias cov enamel tuaj yeem siv rau hauv cov xwm txheej huab cua: nyob rau hauv qhov kub ntawm -30… + 40 °С.

Ntog npaj rau daim ntawv thov silicone enamel

Cov ntaub ntawv tswj hwm kev siv thev naus laus zis ntawm kev siv cov enamel KO-174 - GOST 9-402. Tus txheej txheem hais tias cov hlau kho saum npoo yuav tsum tsis muaj xeb, cov khoom tsis huv, ntsev thiab roj.

Ua ntej kev kho mob, qhov chaw degreased siv acetone, xylene lossis toluene. Cov txheej yog siv tsuas yog tom qab lub hauv paus tau qhuav tag. Lub sijhawm nruab nrab ntawm kev kho thiab xim yuav tsum tsis pub tshaj 6 teev (thaum siv sab nraum zoov). Yog hais tias staining nyob rau hauv tsev, ces tso cai so txog 24 teev.

Cov pob zeb yog npaj rau kev pleev xim raws li SNiP 3.04.03 lossis 2.03.13. Soot, xeb thiab roj raug tshem tawm nrog cov ntaub qhwv thiab cov kuab tshuaj.

Npaj txheej rau kev ua haujlwm

Cov yam ntxwv ntawm cov enamel KO-174 qhia tias kev ua haujlwm nrog cov muaj pes tsawg leeg ntawm hom no tso cai rau qhov kub ntawm -30 txog +40 degrees thiab huab cua av noo mus txog 80%. Txij li cov khoom muag tau npaj txhij, nws tsuas yog yuav tsum tau qhib thiab sib xyaw kom zoo. Thaum cov sediment tau ploj lawm, qhov viscosity ntawm cov enamel yog ntsuas los ntawm viscometer.

Yog tias qhov kev nyeem ntawv ntawm cov cuab yeej txawv ntawm cov uas tau teev tseg hauv daim ntawv pov thawj khoom zoo, koj tuaj yeem nqa cov viscosity ntawm cov khoom ua haujlwm los ze zog rau qhov zoo tagnrho siv toluene thiab xylene.

Kev xaiv ntawm qhov xav tau enamel viscosity yog nyob ntawm daim ntawv thov kev sivtxheej txheej. Yog li, nrog rau cov txheej txheem ntawm staining, kev nyeem ntawv ntawm lub cuab yeej yuav tsum nyob rau hauv 30-40 s. Yog hais tias muaj pes tsawg leeg yog npaj rau pneumatic txau, nws viscosity yuav tsum tau txo mus rau 15-25 s. Rau cov tshuaj tsuag tsis muaj cua, viscosities nruab nrab ntawm 40 thiab 60 s yog suav tias yog qhov zoo tshaj plaws.

Kev siv thev naus laus zis

Ntog kev kho mob hauv qhov chaw nyuaj mus txog yog nqa nrog txhuam txawm tias ua ntej pib pleev xim tag nrho. Qhov chaw ua los ntawm cib, pob zeb thiab plastered hauv paus yog ua tiav hauv 3 txheej, rau ntau hom hlau, ob zaug. painting txaus.

Yog tias silicone enamel KO-174 yog siv los ntawm pneumatic spraying, lub nozzle txoj kab uas hla yog xaiv nyob rau hauv 1.8-2.5 hli, thaum lub siab yuav tsum yog li ntawm 1.5-2.5 kgf. Thaum txau enamel, qhov kev ncua deb ntawm rab phom thiab qhov chaw yuav tsum tau kho yuav tsum yog kwv yees li 200-300 hli.

Tom qab siv cov txheej txheem tiv thaiv thawj zaug, tos ib ntus ntawm 30 feeb, thiab rov pleev xim dua. Yog hais tias muaj pes tsawg leeg yog thov nrog ib tug txhuam los yog cov menyuam, qhov nruab nrab lub sij hawm nce mus rau 1.5 teev (yuav tsum staining ntawm qhov kub ntawm +20 ° C). Nyob rau hauv chav kawm ntawm kev ua hauj lwm, enamel manufacturers pom zoo kom siv lint-free rollers thiab txhuam ua los ntawm ntuj fibers.

Ua tiav ziab ntawm cov khoom tiv thaiv nrog pneumatic txau tshwm sim tom qab 1 teev. Thaum siv manually, lub sijhawm no tuaj yeem txuas ntxiv mus txog 2 teev.

khoom siv

Kev siv cov enamel KO-174 nyob ntawm cov khoom ua tiavnto thiab ntawm txoj kev siv cov txheej txheem tiv thaiv (cov menyuam, txhuam, tshuaj tsuag). Yog li, kev noj cov enamel thaum siv thawj txheej (40 microns tuab) yuav yog kwv yees li 150 g / m 2. Tab sis rau kev kho mob ntawm cov pob zeb hauv av (xws li pob zeb, cib, pob zeb, thiab lwm yam) koj yuav xav tau txog 450 g / m2 ntawm enamel. Nyob rau hauv cov ntaub ntawv no, lub thickness ntawm kev tiv thaiv txheej yuav sib npaug zos rau 80-100 microns.

Yog tias cov hlau siv nyob rau hauv cov huab cua, lub thickness ntawm cov txheej txheej tiv thaiv yuav tsum yog 100 microns. Txhawm rau ua kom tiav qhov xwm txheej no, koj yuav xav tau txog 300 grams enamel ib square meter.

Thaum xam qhov xav tau ntawm cov khoom siv, nco ntsoov tias qhov kev siv tiag kuj tseem nyob ntawm cov xim xaiv. Nws kuj yuav siv sij hawm rau hauv tus account tus naj npawb ntawm cov khaubncaws sab nraud povtseg uas tsim nyog los xyuas kom meej qhov kev tiv thaiv nto. Yuav kom txuag tau nyiaj, ib txoj kev pneumatic ntawm kev siv cov tshuaj muaj pes tsawg leeg. Txhawm rau npaj thawj txheej, koj yuav xav tau txog 180 grams ib m2.

ntsuas kev nyab xeeb thaum staining

Kev ceev faj txog kev nyab xeeb hauv cov txheej txheem ntawm kev siv cov tshuaj tiv thaiv yuav tsum ua raws li kev kawm ntawm txhua tus yam ntxwv ntawm KO-174 enamel. Yog li, cov ntaub ntawv hais tias muaj pes tsawg leeg ntawm cov xim muaj xws li xylene thiab lwm yam kuab tshuaj qhia tau hais tias cov tshuaj tiv thaiv muaj pes tsawg leeg yog heev flammable thiab lom. chav kawm phom sij.

Kev siv cov enamel yuav tsum ua kom txausthaj chaw ventilated. Cov neeg ua haujlwm siv cov hnab looj tes tiv thaiv, lub tshuab ua pa, thiab hauv cov tshuaj pneumatic, tsom iav tshwj xeeb lossis lub npog ntsej muag.

Kev kho deg sab hauv tsev yam tsis tas siv cov cuab yeej tiv thaiv tus kheej raug txwv nruj heev. Nws tseem tsis tuaj yeem siv cov khoom siv hluav taws xob tsim hluav taws xob, haus luam yeeb thaum lub sijhawm staining. Tsis tas li ntawd, cov khoom siv tua hluav taws yuav tsum muaj nyob ntawm qhov chaw ua haujlwm.

Thaum muaj hluav taws, siv xuab zeb, ua npuas ncauj thiab carbon dioxide tua hluav taws. Nws raug tso cai tua hluav taws nrog dej txau zoo.

Zoo kawg

Lub hom phiaj tseem ceeb ntawm KO-174 enamel yog kev tiv thaiv corrosion ntawm cov hlau nto thiab tiv thaiv cov pob zeb ua vaj tse los ntawm cov teebmeem ntawm huab cua. Qhov nrov ntawm cov muaj pes tsawg leeg qhia tau hais tias nws tag nrho copes nrog rau txoj hauj lwm. Txawm li cas los xij, nco ntsoov tias lub txee lub neej ntawm cov khoom no tsuas yog 6 lub hlis xwb, uas ua rau muaj kev pheej hmoo ntawm kev yuav khoom siv tas sijhawm. Ua ntej yuav, koj yuav tsum xyuas hnub ntawm kev tsim cov txheej thiab kev ncaj ncees ntawm lub ntim nws tus kheej.